Heyl & Patterson has been engineering bulk material handling solutions since 1887. In the early 1960s Heyl & Patterson shifted its focus to the exponential growth of the coal and iron industries. Heyl & Patterson identified the need for stacking equipment and started manufacturing stacker/reclaimers to aid in the effective management of coal and iron ore stockpiles.

Read MoreHeyl & Patterson Blog

Tags: bulk material handling equipment, coal handling, stacker/reclaimers

Happy New Year! As we head into a new year many of us resolve to be less stressed, more efficient and in the best shape of our lives. Those same resolutions can often be applied to capital equipment. So while you are setting those goals to improve your well-being in 2016, let us review the ways we can improve the life of our equipment. A few simple preventative maintenance items can make 2016 your continuous barge unloader’s best year yet.

Read MoreTags: barge unloaders, grain, maintenance, coal handling, continuous barge unloader (cbu), upgrades, inspections

Grab Bucket Barge Unloaders for Efficient Inland Waterways

Posted by H&P Blog on Wed, Oct 28, 2015 @ 10:00 AM

Each year, nearly half a million barge loads of bulk material such as coal, grain, wood chips, crushed stone, sand and minerals travel to delivery points along our nation’s inland waterways. River transportation is the safest and most efficient method for moving massive quantities of materials. Ports and other terminals along the rivers utilize various types of unloading systems to quickly and economically offload the barge traffic that comes their way. One such system for unloading barges is the grab bucket barge unloader.

Read MoreTags: barge unloaders, bulk material handling equipment, coal handling, grab unloaders

Heyl & Patterson Compares Railcar Unloading Methods in World Coal

Posted by H&P Blog on Wed, Jun 24, 2015 @ 09:00 AM

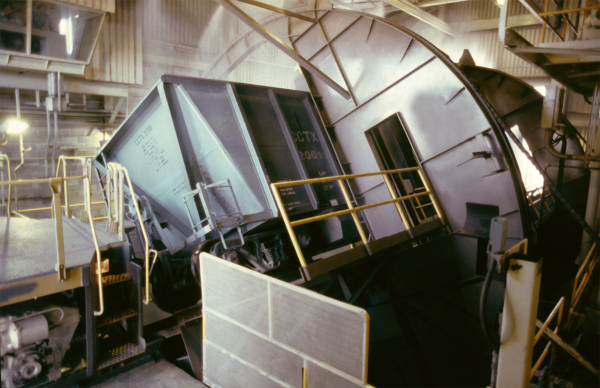

Unloading railcars is usually accomplished in one of two ways: a railcar dumper turns cars upside down in order to spill their contents, or bottom dump railcars drop their contents through chutes and gates. There are obvious differences between the two methods, but also some surprising similarities. Choosing between these systems calls for a number of factors to be considered, namely capital costs, maintenance, climate, versatility and economics. Heyl & Patterson recently explored both sides of the matter in an article published in World Coal magazine's June 2015 issue, entitled "Which Unloading System?"

Read MoreTags: bulk material handling equipment, coal handling, wagon tipplers, railcar dumpers

Frigid Conditions Call for a Hammermill When Unloading Bulk Materials

Posted by H&P Blog on Wed, Jan 14, 2015 @ 03:00 PM

Tags: bulk material handling equipment, coal handling, hammermill

Since 1875, the United States has been one of the world's main steel producers. Steel has been an important factor in the American economy for over 100 years, providing jobs to many generations of American families, and it continues to be a booming industry today. Production of steel takes place in two different ways. One method uses integrated smelting involving a blast furnace, followed by a basic oxygen furnace, and the other involves an electric arc furnace.

Tags: coal handling, coke, railcar dumpers

Heyl & Patterson to Exhibit at 2013 Coal Handling & Storage Conference

Posted by H&P Blog on Wed, Oct 16, 2013 @ 10:35 AM

Coal is primarily used as a solid fuel to produce electricity and heat through combustion. World coal consumption was 7.99 billion tons in 2010, and is expected to increase 48% to about 9.98 billion tons by 2030. Coal can be delivered by truck, rail, barge or ship, and some power plants are even situated near coal mines so coal can be delivered by conveyor systems.

Tags: Heyl & Patterson, trade shows & conferences, coal handling

The Continuous Barge Unloader vs. the Grab Bucket Unloader

Posted by H&P Blog on Wed, Jun 06, 2012 @ 10:41 AM

The first appearance of the Continuous Barge Unloader, or CBU, in the United States was in steel mill applications. Although primarily used for iron ore offloading, the machines also saw early use as coal and coke unloaders. Different styles of CBUs were applied to specific projects as determined by water level fluctuations, barge size and needed discharge capacities. The CBU offered numerous advantages over the traditionally employed clamshell or grab bucket style barge unloader.

Tags: barge unloaders, bulk material handling equipment, coal handling, ship unloaders

Heyl & Patterson to Exhibit at Electric Power Conference

Posted by H&P Blog on Wed, May 02, 2012 @ 09:40 AM

The approval of new regulations from the Environmental Protection Agency regarding air pollution, water pollution and waste disposal could result in the retirement of 35-70 gigawatts of coal-fired power generation nationwide. Electricity rates will most certainly rise, and many believe that even if construction jobs are created in the green industry, virtually no manufacturing jobs are likely to be created from the replacement of coal. Transmission grid stability will emerge as a major issue, both because of power plant shutdowns and the intermittency of renewables.

Tags: Heyl & Patterson, trade shows & conferences, bulk material handling equipment, railcar movers, coal handling, wagon tipplers, railcar dumpers

The main purpose of coal handling systems is to transfer the coal as quickly and cleanly as possible as it is moved from one place to another. Loading and transporting are just two stages in the process of moving coal from the producer to the consumer. When transporting by rail, coal must be unloaded from railroad cars and a number of options are available, including rotary dumpers and turnover dumpers, which discharge loads parallel to the rails.

Tags: railcar movers, side arm chargers, railcar indexers, CUB railcar mover, train positioners, coal handling, wagon tipplers, railcar dumpers