Heyl & Patterson has been engineering bulk material handling solutions since 1887. In the early 1960s Heyl & Patterson shifted its focus to the exponential growth of the coal and iron industries. Heyl & Patterson identified the need for stacking equipment and started manufacturing stacker/reclaimers to aid in the effective management of coal and iron ore stockpiles.

Read MoreHeyl & Patterson Blog

Tags: bulk material handling equipment, coal handling, stacker/reclaimers

Rehabilitating Aging Bulk Material Handling Equipment

Posted by H&P Blog on Wed, Oct 23, 2019 @ 03:10 PM

Bulk material handling equipment is an investment, it’s a large expense, and its useful life is often measured in decades. But what happens when that useful life comes to an end after 40 years of service, and there is no capex budget for a replacement? That's when H&P steps in to help you rehabilitate aging equipment for a longer future of material handling. H&P will help customers to progressively replace equipment components to return aging machinery back to its original specs.

Read More

Tags: bulk material handling equipment, power generation, upgrades

Railcar Movers Keep Urea Processing Plants Pushing Forward

Posted by H&P Blog on Wed, Dec 16, 2015 @ 10:00 AM

Urea, sometimes called carbamide, is a solid organic crystalline compound that is colorless, odorless and highly water soluble. It is formed naturally in mammals, and serves an important role in the liver as the main nitrogen-containing product that breaks down amino acids, proteins and ammonia into waste. The kidneys scrub the urea from the blood and deposit it into the urinary tract, and it then makes up the chief solid material dissolved in urine. Urea can also be synthesized inexpensively from abundantly available inorganic materials. Because urea offers wide-ranging uses in many different industries, it is produced regularly and is available in large quantities for use throughout the world.

Read MoreTags: bulk material handling equipment, railcar movers, fertilizer, railcar indexers, CUB railcar mover, train positioners

Grab Bucket Barge Unloaders for Efficient Inland Waterways

Posted by H&P Blog on Wed, Oct 28, 2015 @ 10:00 AM

Each year, nearly half a million barge loads of bulk material such as coal, grain, wood chips, crushed stone, sand and minerals travel to delivery points along our nation’s inland waterways. River transportation is the safest and most efficient method for moving massive quantities of materials. Ports and other terminals along the rivers utilize various types of unloading systems to quickly and economically offload the barge traffic that comes their way. One such system for unloading barges is the grab bucket barge unloader.

Read MoreTags: barge unloaders, bulk material handling equipment, coal handling, grab unloaders

Heyl & Patterson Compares Railcar Unloading Methods in World Coal

Posted by H&P Blog on Wed, Jun 24, 2015 @ 09:00 AM

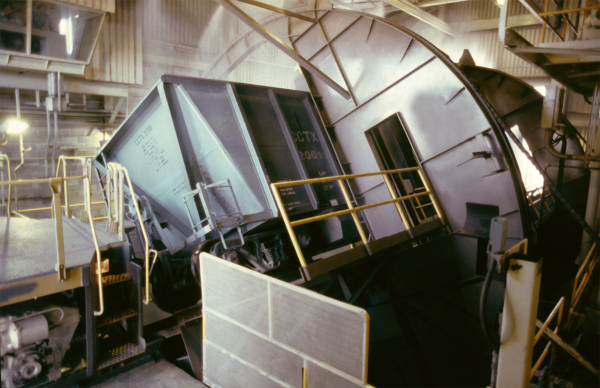

Unloading railcars is usually accomplished in one of two ways: a railcar dumper turns cars upside down in order to spill their contents, or bottom dump railcars drop their contents through chutes and gates. There are obvious differences between the two methods, but also some surprising similarities. Choosing between these systems calls for a number of factors to be considered, namely capital costs, maintenance, climate, versatility and economics. Heyl & Patterson recently explored both sides of the matter in an article published in World Coal magazine's June 2015 issue, entitled "Which Unloading System?"

Read MoreTags: bulk material handling equipment, coal handling, wagon tipplers, railcar dumpers

Why Upgrade Existing Bulk Material Handling Equipment?

Posted by H&P Blog on Tue, Apr 14, 2015 @ 09:04 AM

An all-too-painful truth is that bulk material handling equipment breaks down over time, and whenever it occurs, it's almost always costly. The most common problems that lead to breakdowns are actually quite preventable. They include improper maintenance, overrunning a machine's capability, not replacing worn parts, poor electrical connections, and even operation by untrained personnel or not consulting the operator manual. Almost all mean that someone has ignored the warning signs of an impending stoppage. These problems account for most of the breakdowns seen in the field, and all are avoidable by taking some simple precautions.

Read MoreTags: trade shows & conferences, bulk material handling equipment, power generation, upgrades

Unloading Wood Chips for the Production of Paper Pulp

Posted by H&P Blog on Wed, Mar 25, 2015 @ 09:48 AM

Even in today's "paperless" world, there continues to be a huge demand for paper. Paper is made from wood pulp, which is also used to manufacture a wide variety of products from diapers to particle board to textiles. The pulp itself is the cellulose, lignin and hemicellulose components of wood fibers, which are separated from one another through steaming, cooking or mechanical grinding processes. Most pulp is made from a mixture of sawmill residue, logs, wood chips and recycled paper, and it is interesting to note that practically all of the fibers that end up as pulp originally existed as trees.

Tags: bulk material handling equipment, wagon tipplers, biomass, pulp & paper, wood chips, railcar dumpers

Frigid Conditions Call for a Hammermill When Unloading Bulk Materials

Posted by H&P Blog on Wed, Jan 14, 2015 @ 03:00 PM

Tags: bulk material handling equipment, coal handling, hammermill

Prior to the Civil War, cities in the Ohio and Mississippi Valleys such as Pittsburgh and St. Louis were wholly dependent upon steamboats as a means of transporting bulk materials. Even after barges entered service, they were unloaded by hand because unloading machines had not yet been developed. Productivity improved along with technology, and new processes were developed for machinery production and mechanization.

Tags: Heyl & Patterson, trade shows & conferences, barge unloaders, bulk material handling equipment, continuous barge unloader (cbu)

Bulk Material Handling Equipment Keeps Products Moving

Posted by H&P Blog on Wed, Jun 25, 2014 @ 09:37 AM

Bulk material handling equipment has evolved over many years. Some of the materials being transported have changed, such as specialized sands used in the oil and gas industry and new potential energy sources such as biomass, plus the volumes have increased and the terminals have become much more sophisticated. Even so, many of the basics in the industry have remained the same over the years.