The railcar, as a means of transporting bulk materials, has been in existence for 400 years and actually pre-dates the steam locomotive by 172 years. The first railcars were horse drawn and hauled coal along wooden railway tracks. The shovel, with a good measure of human sweat, was the accepted method of loading and unloading it.

Heyl & Patterson Blog

Heyl & Patterson Announces 2012 Dumper User Group Conference

Posted by H&P Blog on Wed, Jan 18, 2012 @ 10:13 AM

Railcar unloading has become more advanced and complicated since Heyl & Patterson was established in 1887. In 1984, Heyl & Patterson developed a means to help customers meet the challenges of working with Rotary Railcar Dumpers through an industry first: a conference designed specifically for users of dumpers and related systems. The conference has been a bi-annual event ever since, and has provided genuine benefits to all who attend.

Tags: Heyl & Patterson, trade shows & conferences, wagon tipplers, railcar dumpers

Proper Railcar Dumper Maintenance Extends Operational Life

Posted by H&P Blog on Wed, Dec 07, 2011 @ 11:03 AM

Few things are built to last these days. Even fewer are built to last a century. Heyl & Patterson recently provided replacement parts for equipment built in 1913. To put that in perspective, when that particular machine went into service, the Ford Motor Company had introduced the first moving assembly line, the Lincoln Highway became the first road to cross the United States and the modern zipper had just been invented.

In order to be useful for several decades, Rotary Railcar Dumpers must be properly maintained. Heyl & Patterson offers replacement parts and upgrade services, for our own products as well as for those made by other manufacturers. In addition to increasing the life of a dumper, upgrades and replacement parts make the work environment safer and elevate a dumper’s performance and efficiency, saving time and money.

Custom upgrades are one way to ensure the long life of a dumper. Heyl & Patterson can convert an existing dumper into one capable of handling heavier loads more easily and securely. Upgrades also permit dumper owners to better plan and provide for capital expense efficiencies by identifying parts that need replacement, rather than necessitating a more extreme overhaul in the case of an emergency repair.

Dumper upgrades include a full array of field-tested enhancements that customers can use once or on a continual or as-needed basis, in order to accommodate heavier loads with greater reliability and reduced maintenance costs. Several innovative designs permit a more uniform spread of weight, which decreases the potential for future problems while extending dumper life.

Mechanical upgrades increase dumper reliability as they decrease the possibility of an unexpected breakdown. Electrical upgrades are engineered to ensure peak performance, smoother operation, and reduced wear with added safety features.

In addition to upgrades, proper maintenance is essential to ensuring durability and longevity. Proper maintenance includes periodic inspections to ensure operating efficiency. These inspections catch problems in their initial stages before they become catastrophic, and they identify necessary upgrades.

Necessary inspections include visual, mechanical, structural and electrical evaluations. Inspections evaluate the need for adjustment, maintenance, monitoring and/or replacement. Heyl & Patterson's four-part process comprises a comprehensive inspection program. These steps include:

- A review of the dumper’s inspection history and maintenance program, including a list of recommended spares in inventory, as well as problems and concerns

- A visual inspection of the structural integrity of mechanical components, focusing on critical adjustments and key components

- Observation of normal operating conditions to identify critical issues and to recommend required tune-ups

- A handwritten report of the inspection results, and a more formal follow-up that clearly explains exactly what was inspected, problems detected and recommended solutions

In addition to an inspection service, Heyl & Patterson offers field service as a portion of its maintenance services in order to extend the life of a dumper. Field services include consultation on parts installations, outage planning, maintenance recommendations, upgrades and start-up assistance. In addition, Heyl & Patterson offers engineering studies to monitor equipment and maintain peak operating performance, reliability, and life of the equipment. With proper maintenance and upgrades, a dumper can last more than a lifetime.

For more information on Heyl & Patterson's railcar dumper upgrades click here,

Tags: maintenance, upgrades, inspections, railcar dumpers

Lionel is the most enduring brand name associated with American model trains, with a devoted following of collectors. Lionel products are O-gauge, meaning a 1:48 scale (a quarter inch equals one foot) to show fine detail. Inside Track magazine, the official publication of the Lionel RailRoader Club, recently contacted Heyl & Patterson regarding our Rotary Railcar Dumpers because one of their newest accessories is a scale model dumper. The article will be in the December 2011 issue.

Heyl & Patterson to Exhibit at Power-Gen International

Posted by H&P Blog on Tue, Nov 22, 2011 @ 12:25 PM

Power generation comes from a variety of heat-producing sources: oil, natural gas, nuclear, geothermal, wind, solar and of course, coal. The heat boils water and creates steam. The steam, under high pressure, spins a turbine. The turbine interacts with a series of magnets to produce electricity, which is transmitted as moving electrons through a series of wires to homes and businesses.

Tags: Heyl & Patterson, trade shows & conferences, barge unloaders, industrial dryers, coal handling, coal dryers, railcar dumpers

The rotary railcar dumper is an effective, time-tested machine for transferring bulk materials, especially for unloading coal at power plants. The rotary dumper makes unloading coal a quick and simple process that eliminates waste while saving time and money. Heyl & Patterson has manufactured Rotary Railcar Dumpers for decades, and is one of the companies that pioneered the technology.

Tags: wagon tipplers, railcar dumpers

Seevinck & Associates Represents Heyl & Patterson in Australia

Posted by H&P Blog on Wed, Aug 17, 2011 @ 08:58 AM

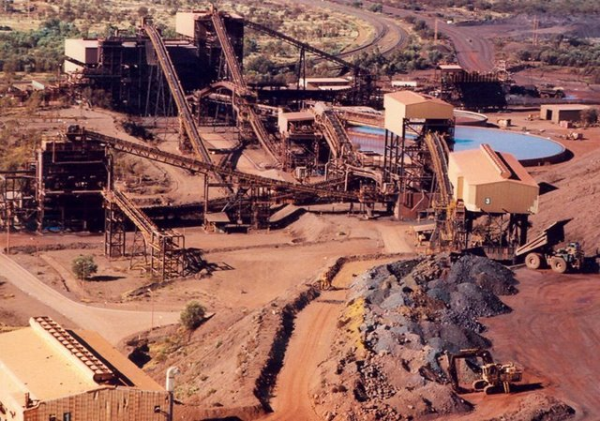

Mining is one of Australia's most important industries, creating significant employment and greatly contributing to the Australian economy. It's also a vital source of export revenue. Australia is the world's leading exporter of coal and iron ore, and is among the leaders in nickel, zinc, aluminum, gold and uranium. Minerals make up about 35% of Australia's total exports.

Tags: barge unloaders, reps, bulk material handling equipment, railcar movers, side arm chargers, railcar indexers, train positioners, coal handling, wagon tipplers, ship unloaders, railcar dumpers

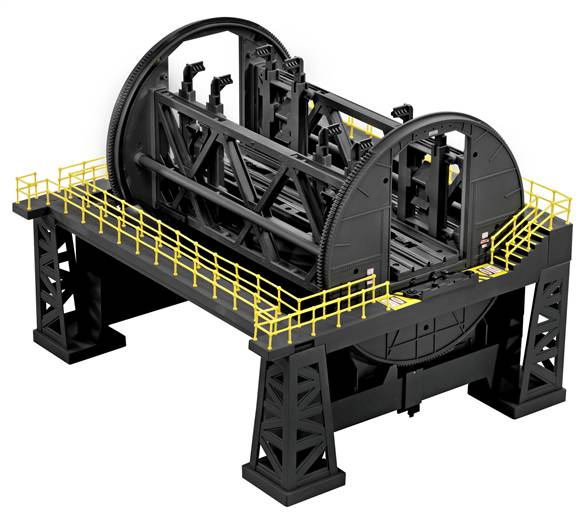

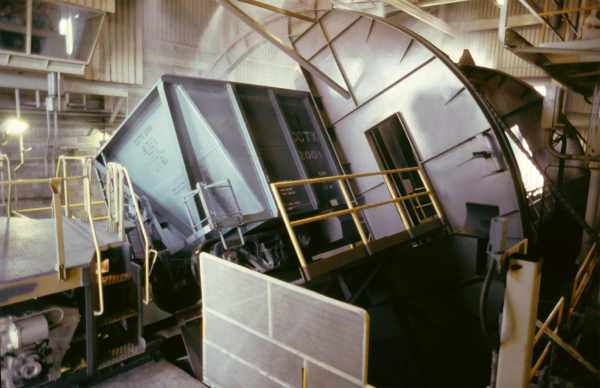

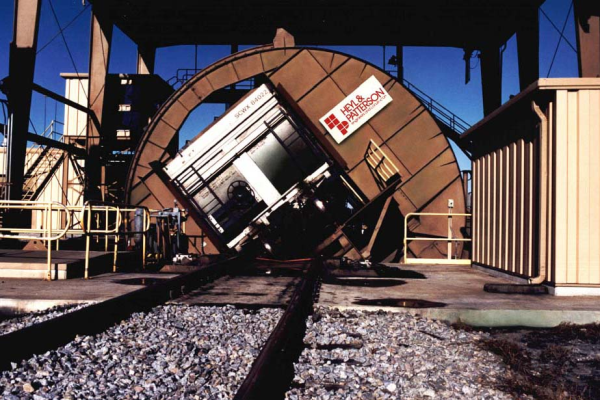

As the name implies, Rotary Railcar Dumper Unloaders are used to unload certain types of railroad cars. Dumpers hold a car to a section of track and rotate the track and car together to dump out the contents. Heyl & Patterson machines feature high speed semi-automatic dumping, rotation times as fast as 35 seconds per car and a dumping rate of 10,000 tons per hour when configured in tandem. Our dumpers can be controlled by just one operator and are ideal for random car or unit train applications.

Tags: trade shows & conferences, barge unloaders, bulk material handling equipment, railcar movers, railcar dumpers

Indonesia is one of the largest coal producers and coal consumers in the world. Over the past two decades, Indonesia's coal industry has transformed itself from being an unknown, minor player in Asia's coal markets to the world's largest exporter of steam coal. Indonesia created this world-scale industry despite challenges created by widespread government corruption, a weak legal system, the Asian Financial Crisis of 1997 and the fall of the Suharto government in 1998.

Tags: barge unloaders, bulk material handling equipment, coal handling, wagon tipplers, ship unloaders, railcar dumpers

The fundamental principles of electricity generation were discovered in the early 1800s by British scientist Michael Faraday. The basic method is still in use today — electricity is generated by turbines that are turned by pressurized steam, which is produced by burning some form of fuel. This is the first process in the delivery of electricity to electric utility customers. The other processes, which are transmission, distribution, storage and recovery, are carried out by the electric power industry.

Tags: Heyl & Patterson, trade shows & conferences, barge unloaders, bulk material handling equipment, railcar dumpers